- Suppliers

-

GPM

GPM | Tailored Turrets for Every Machining Need

About Company

Established in 2008, GPM Co., LTD is a joint venture between GP Machinery Co., LTD and Sauter. GPM delivers instant, professional services, collaborating with local machine tool manufacturers to enhance MIT products' quality and competitiveness. Focused on innovation and sustainability, GPM offers one-stop solutions and integrates CO2 reduction into product development. Our customizable turrets meet diverse machining needs, reinforcing GPM's global market leadership.

Products

.png?width=3840&height=2714&name=Premier%20series(8000rpm).png)

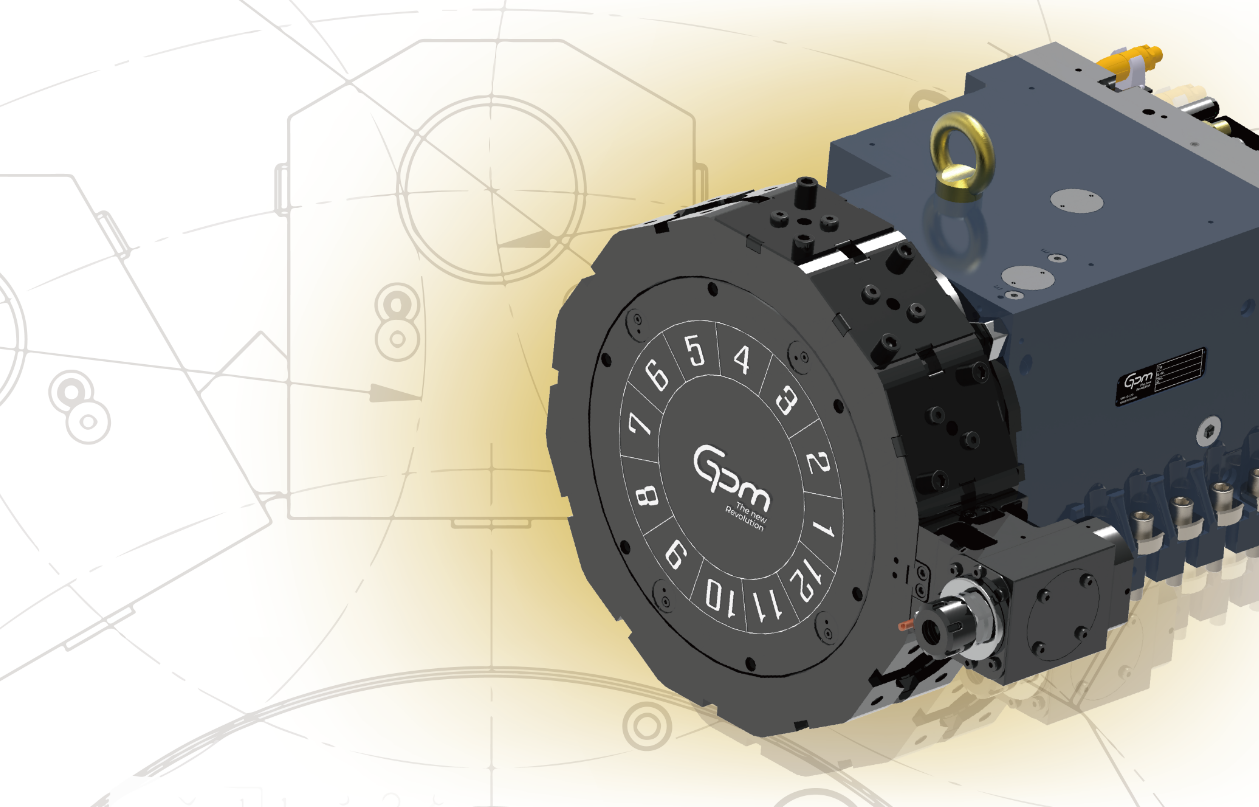

Premier series

The Premier Series excels with high-speed performance and excellent thermal management. It operates up to 8000 rpm, supporting up to 24 hours of continuous processing at 6000 rpm, and 2 hours at 8000 rpm with less than 10µm thermal displacement and temperatures below 65°C. The battery-free B3 indexing motor boosts tool holder capacity, while the system offers high coolant pressure up to 150 bar. Designed for durability and efficiency, the Premier Series is perfect for demanding machining tasks.

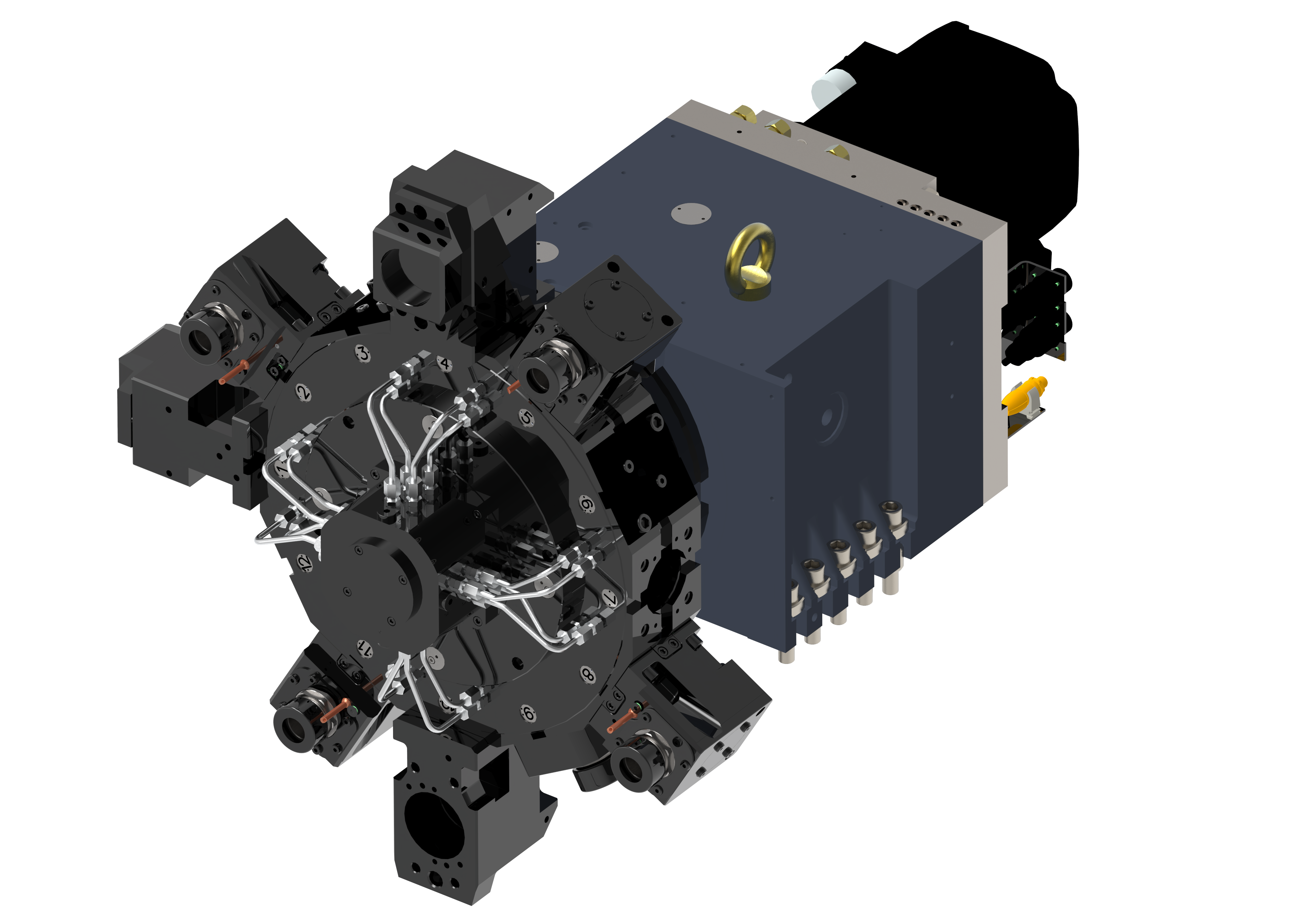

ATC Turret

The ATC Turret with Quick Change boosts automation and efficiency with its rotary distributor for automatic tool changes. It features a 5-channel system for hydraulic clamping, coolant delivery, air blasting, and probe detection. Supporting Industry 4.0 standards, this turret includes a front-end rotating mechanism compatible with robotic arms and offers customizable designs to meet specific machine needs.

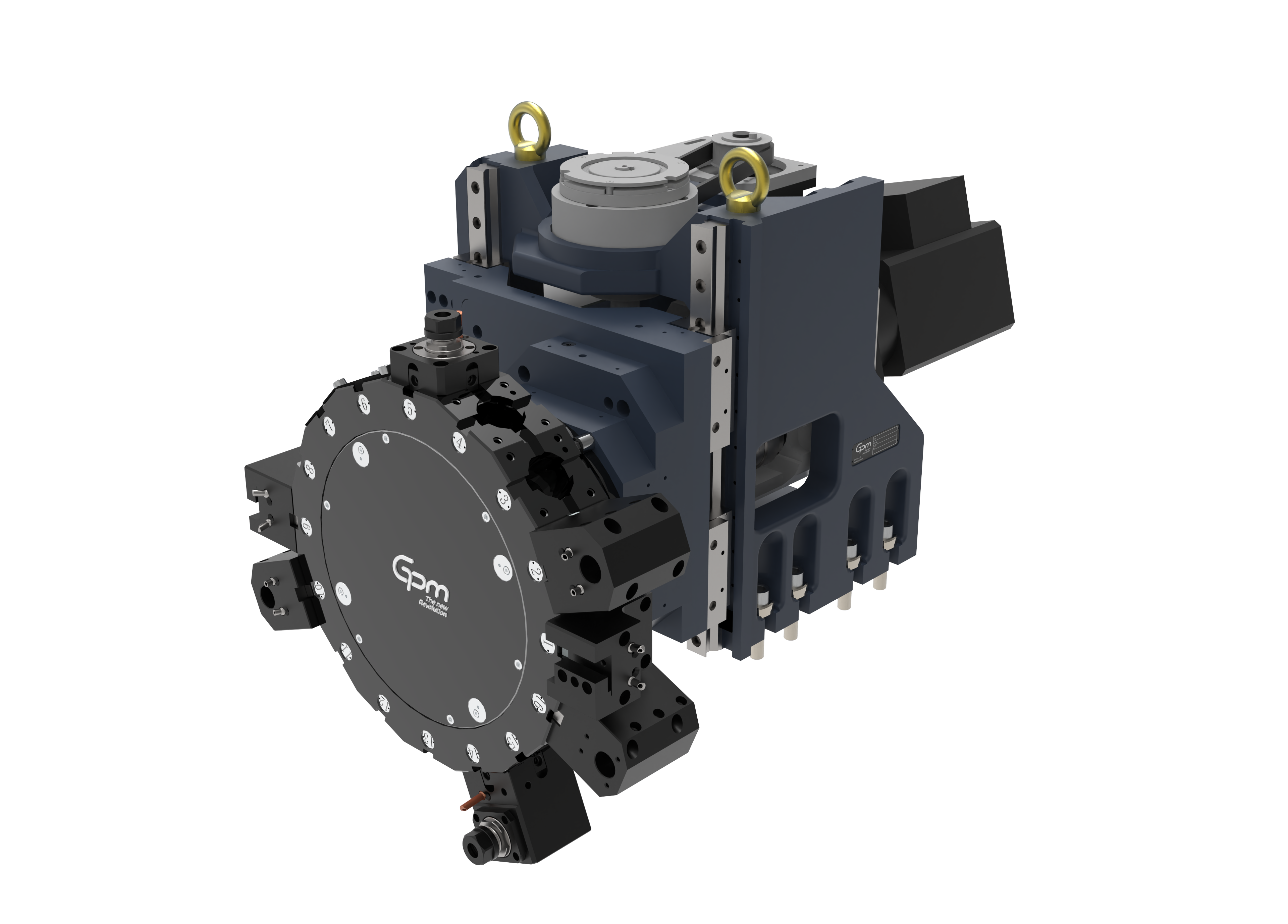

Driven Turret with Y axis

The Driven Turret with Y Axis offers advanced machining flexibility and performance with two mounting options: external and central. The external mount, suitable for single or dual-spindle machines, features 2 linear guides and 1 ball screw for stability, with Y-axis travel of ±50~60mm and an electromagnetic brake, plus an optional motor brake. The central mount, with 4 linear guides and a central screw, reduces interference by 30%, making it ideal for medium to light cutting and inclined bed configurations. Both designs ensure precision and durability, excelling in various machining environments.