Energy Saving in

Smart Manufacturing

MINZ

MINZ Inc. is a leading pioneer in production saving of shoe manufacturing and Energy saving services. CutBot is designed for smart manufacturing with nesting, cutting, and material feeding automation. It's equipped with remote task dispatching and IoT functions.

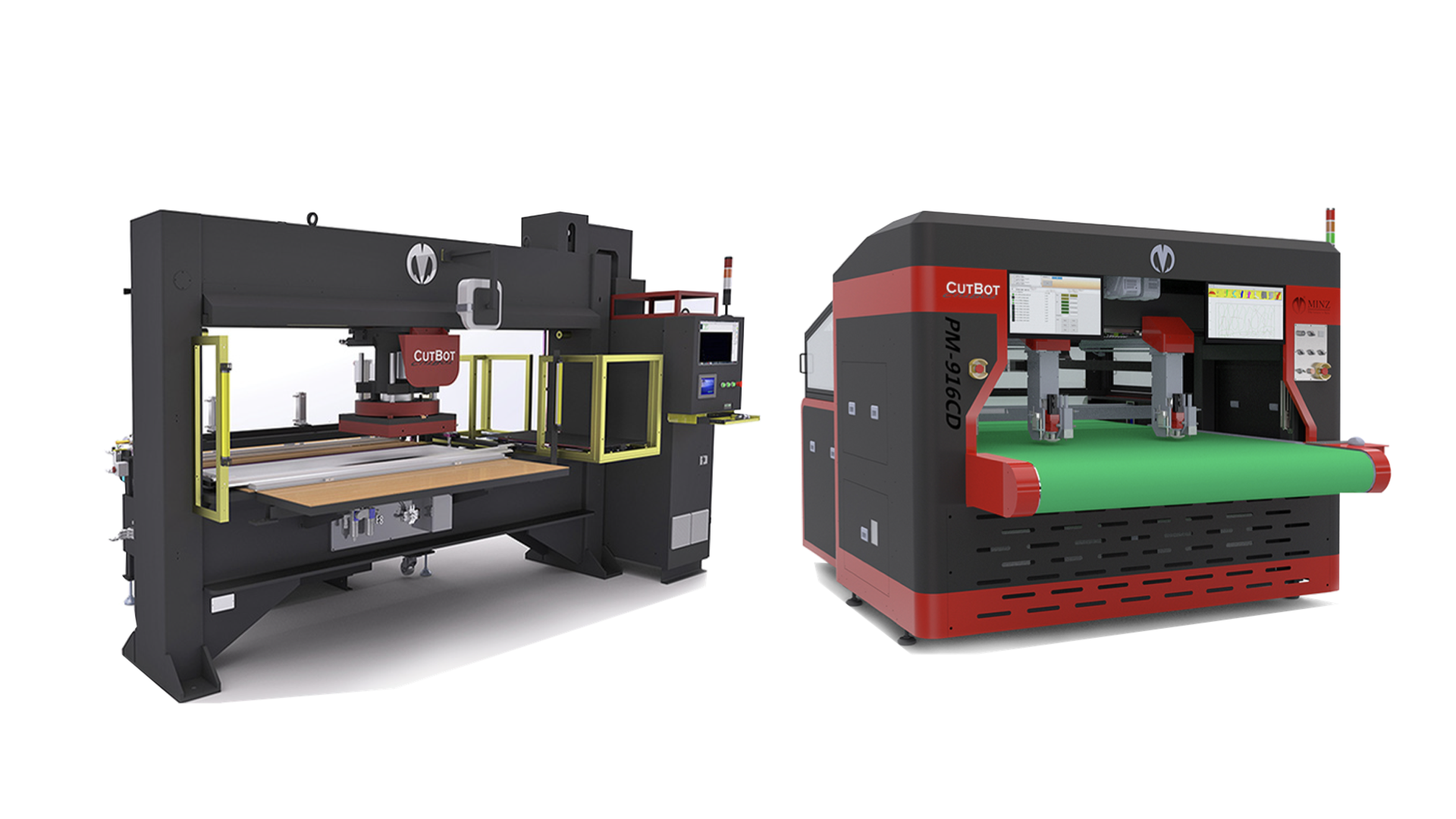

Oscillating CutBot

Stroke Cutting CutBot

TAITRA will provide relevant industry and company product information through email from time to time.

In the future of smart manufacturing, energy saving matters.

With the MINZ Energy System installed, an average of 23 kwh is saved each hour, equivalent to US$ 22,000 in electricity savings per year.

Also, your machine's motor and hydraulic fluid temperatures are decreased to room temperature, significantly improving your working environment.

The chiller can also be turned off to save on additional electricity consumption. Hydraulic fluid's lifetime is doubled as well. Furthermore, a servo system's precise injection can help reduce production defects and material waste.

Well-known shoe brands such as Bata, All-Star, Crocs, Sketchers, Ferrari, and Daphne have saved more than 50% on electricity consumption with our Energy Saving System.

Our Smart Box for IoT comes with advanced two-way monitoring and controlling to ensure machine settings match production standards, achieving better production quality for your factory.

It collects multiple data types for monitoring, including temperature, pressure, production output, and speed. It also has a spare parts lifecycle auto-counting and notification function.